Our services

Oil and Gas

Absun Zolal is ready to provide water, electricity, and steam supply for steel, petrochemica

Oil and Gas

Absun Zolal is ready to provide water, electricity, and steam supply for steel, petrochemica

Seawater desalination

Each sea has a special chemical composition. The salinity level and the water analysis of every seawater

Seawater desalination

Each sea has a special chemical composition. The salinity level and the water analysis of every seawater

Wastewater Reuse

By virtue of over a decade of professional wastewater Reuse activities, Absun now specializes in

Wastewater Reuse

By virtue of over a decade of professional wastewater Reuse activities, Absun now specializes in

Industrial water treatment

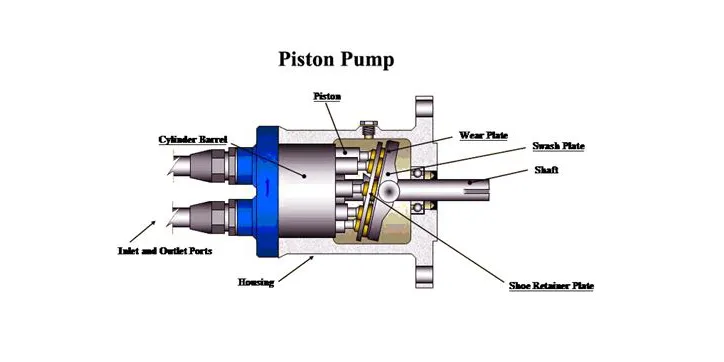

Industrial water treatment is often done using one or a combination of the following Reverse osmosis

Industrial water treatment

Industrial water treatment is often done using one or a combination of the following Reverse osmosis

Selected projects

Persian Gulf Water Desalination

Pars Oil and Gas Co. (POGC)

Water & Wastewater Treatment

Kermanshah Petrochemical Co.

Open Circuit Cooling Tower(Wet)

Tehran Oil Refining Co.

Water Treament Plant

Shazand Oil Refinery Co.

Comments

Isfahan Oil Refinery, as the first industry in the world, and the ability of Iranian specialized forces to choose a project in cooperation with one of the best water companies in Iran, with a capacity of 22,000 cubic meters per day, refines wastewater.

Engineer Nazaripour

Isfahan oil refining

In order to achieve the goals of dealing with drought and optimal water consumption, Absan Zalal Company has localized such systems in the country by using talented human capital and using modern technology. Hoping for more success for this company.

Engineer Ronaghi

Codetic

Absun Zolal Middle East Company, while having world-class knowledge and nearly two decades of valuable experience in the field of water treatment and industrial wastewater, and relying on its experienced, expert and committed forces, is proud to be a small share in the growth path. And the promotion of the industry has removed this border.

Engineer Amiri

Project control manager

Send resume

Absun Zolal Company announces its readiness to recruit active, specialized and committed workers. Those interested can fill and send the recruitment form.

Employers